Client Background: Customer uses aluminum to manufacture aerosol cans

Application: Remove elevated levels of oils and solids from a waste stream

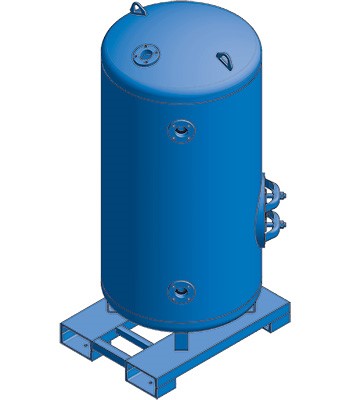

Our Solution: Supply a complete turnkey system to remove oils and solids from the waste stream. The system includes Oil Water Separators to remove oils, Chemical Addition Systems, Inclined Plate Clarifiers, and Neutralization Tanks to remove the solids, and a final sample tank to measure pH, turbidity and hardness.