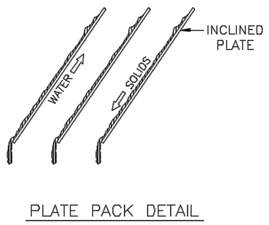

The Westlake Environmental IPC uses a series of inclined plates that create a large settling area in a small footprint. The inclined plates sit at a 55° angle and are assembled in a pack configuration. Descending solids settle on the top of the plates and descend into the sludge chamber, while the clean water flows upward along the bottom of the plates and into the effluent chamber. See illustration:

Inclined Plate Clarifier Process: Raw water enters the WIPC inlet chamber and is immediately dispersed through a non-clog diffuser across the width of the clarifier, which reduces velocities and turbulent flow, and begins the settling process. The flow leaves the inlet chamber under a weir that directs the flow evenly under the plate pack for heavier solids settling. Fines in the water then begin a vertical path through the plate pack and stop their vertical motion, fall downward to the plate surfaces beneath them and descend into the sludge chamber. Clean water flows upward along the bottom of the plates into the effluent chamber prior to discharge via an effluent flange.

Removal Efficiencies: The Westlake Environmental Inclined Plate Clarifier effectively removes suspended solids and precipitated metals from a waste stream. With proper chemical pre-treatment, the suspended solids in the effluent are often less than 10 mg/L. The solids concentration of the sludge material typically ranges between 2% to 3%.

This proven design has made the Westlake Environmental IPC a preferred tool for Engineers, Contractors and End Users. Call today for more information on the Westlake Environmental Inclined Plate Clarifier.