GENERAL INFORMATION

The Westlake Environmental Emulsion Cracking System (ECS) is highly efficient in removing free, dispersed and emulsified hydrocarbon products from a waste stream. The model ECS is a modified Oil Coalescing Separator that includes a chemical treatment step both upstream and downstream of the separator for removal of emulsified oils. Lowering the pH of the incoming water destabilizes the petroleum hydrocarbon oil water ionic bond, allowing the oil to become free. The free oil is then removed in the oil coalescing chamber of the ECS tank. The system is completely integrated and skid mounted.

OPERATION

The Westlake Environmental Emulsion Cracking System (ECS) is highly efficient in removing free, dispersed and emulsified hydrocarbon products from a waste stream. The model ECS is a modified Oil Coalescing Separator that includes a chemical treatment step both upstream and downstream of the separator for removal of emulsified oils. Lowering the pH of the incoming water destabilizes the petroleum hydrocarbon oil water ionic bond, allowing the oil to become free. The free oil is then removed in the oil coalescing chamber of the ECS tank. The system is completely integrated and skid mounted.

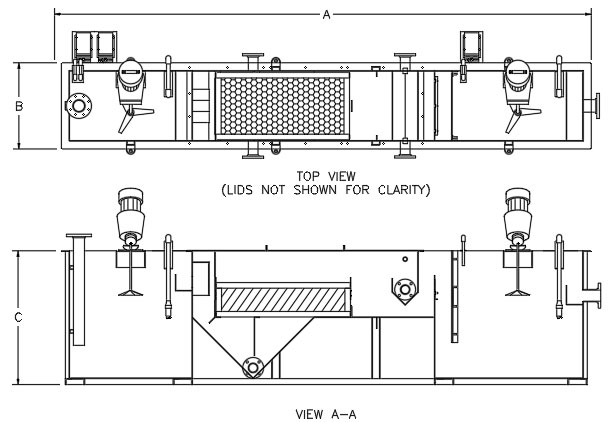

Three stage treatment system is complete with gravity flow through a single skid. System includes chemical feed systems, mixers, pH controllers and controls for all mechanical devices. Raw water enters the initial chamber of the ECS where a pH adjustment and/or an emulsion breaking chemistry are added and mixed to break the emulsions. Oil/water separation begins in this chamber. Water leaving the initial chamber continues to the Oil Coalescing Separator portion of the tank where the free oil is removed. Clean water continues to the final chamber pH is neutralized prior to discharge. Operation is completely automatic and requires only periodic calibration and check to ensure proper operation.

APPLICATIONS

• Aircraft Maintenance

• Can Manufacturing

• Groundwater Remediation

• Refineries

• Pulp & Paper Mills

• Ballast Water

• Chemical Processes

• Manufacturing Plants

• Groundwater

• Tank and Truck Wash

• Bilge Water

• DAF Pretreatment

MATERIALS OF CONSTRUCTION

Materials of construction include 3/16”-1/4” A36 carbon steel, 304 and 316 stainless steel. The standard Westlake Bundle material is Polyvinylchloride (PVC) which is highly oleophilic. The media can also be supplied in CPVC and 304 stainless steel. Plate spacing ranges from 1/2” to 1.2”, 3/4” is standard.

AVAILABLE OPTIONS

• Complete Pump Packages

• Sludge Auger

• Level Switches

• Custom Tank Design

• Optional Media Materials

• Freeze Protection

• NEMA 7 Controls

• Custom Control Logic to Satisfy Your Application

EMULSIONS DEFINED

Emulsions are defined as a material consisting of a mixture of liquids that do not dissolve in each other and having droplets of one liquid scattered throughout the other, such as oil in water. Droplet sizes are typically less than 20 micron. Emulsions are created two ways, mechanically and chemically.

CHEMICAL EMULSION

Chemical emulsions are created when surfactant chemicals are used, such as soaps, detergents or high pH cleaners. The chemicals restrict the natural process of oil droplets joining, or coalescing, and create a stabilized emulsion. Typically an emulsion breaking chemistry is required as chemical emulsions rarely separate by themselves.

MECHANICAL EMULSION

Mechanical emulsions occur thru a mechanical means such as a pump, mixer or other mechanical device that shears the oil droplets into smaller droplets. These types of emulsions take an excessive amount of time to separate naturally so chemistry is used to expedite the process.