WHAT IS A FILTER PRESS

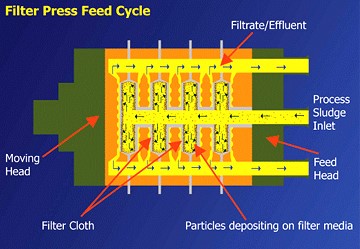

The Westlake Environmental Filter Press (FP) is a fixed volume, batch pressure filter that separates liquids and solids. After the plates are compressed together hydraulically, slurry is pumped into the filter press and dewatered under pressure. The process uses the principle of pressure drive, as provided by a slurry pump. As a fixed volume filter, it requires a specific quantity of solids in the total influent stream for the press to work effectively, and if not filled to capacity with solids the filter cake will not reach its maximum potential for dry cake thickness. Pressure is used as the driving force in the separation process.

OPERATION

A set of filter plates with clothes are sandwiched together in series. Once the plates are compressed together hydraulically, fluid is pumped into the center of the filter plates with all chambers being filled simultaneously. The solids are retained on the filter clothes, which act as a depth filter for liquid/solid separation, while clean fluid (Filtrate) travels thru to the discharge manifold and exits the press. When the filter plates are full, the cycle is complete, and the filter press is opened to discharge the solids off each plate.

WHAT’S INVOLVED

The filter press consists of a head and follower that contain a series of plates that are supported by side bars or overhead beams. The head serves as a fixed end to which the feed and filtrate pipes are connected. The follower moves along the side bars and presses the plates together during the filtration cycle by a hydraulic or mechanical mechanism. Each plate includes filter cloth on both sides and, once pressed together, they form a series of chambers. The plates have a centered feed port that passes through the entire length of the filter press so that all the chambers of the plate pack are connected together. Likewise, four corner ports connect all the plates and collect the filtrate in a “closed discharge” towards outlets that are located on the same side as the feed inlet.

APPLICATIONS

- Chemical Processing

- Glass Manufacturing

- Metal Finishing and Plating

- Plastic Recycling

- Steel Processing

- Concrete

- Laundry and Textiles

- Mining and Minerals

- Produced Water

- Stone and Granite

- Food and Beverage

- Lime Softening

- Pharmaceuticals

- Pulp and Paper

- Vehicle Wash

A recessed filter plate is made up of polypropylene squares with a concave depression and a hole in the center of each. Two plates join together to form a chamber to pressurize the slurry and squeeze filtrate out through the cloth lining in the chamber.

AVAILABLE OPTIONS

- Semi Auto/Automatic Plate Shifter

- Air or Electric Hydraulics

- Automatic Cloth Washer

- Platform

- Self Dumping Dumpsters

- Air Operated Feed Pump

- Light Curtain

- Automatic Drip Trays

- Extended Legs and Chutes

- Automatic Feed Pump Control System (AFPCS)