GENERAL INFORMATION

The Westlake Environmental Inclined Plate Clarifier (IPC) is designed for settling solids and precipitated metals. One of the more desirable features of the IPC is its compact design. The units easily fit in tight locations with low ceiling height and do not require expensive access platforms for maintenance. With proper chemical pre-treatment, the suspended solids in the effluent are often less than 10 mg/L.

The IPC is unique in the industry offering many advantages over conventional plate clarifiers.

✓ Large inlet water chamber to dissipate the dynamic energy of the water and distribute the flow.

✓ Solids settle directly into the sludge chamber. Only fines and clarified water enter the inclined plates.

✓ Plate spacing of one inch allows twice the projected settling area per clarifier volume.

✓ An optional full width stainless steel auger is offered to convey sludge to a single discharge port.

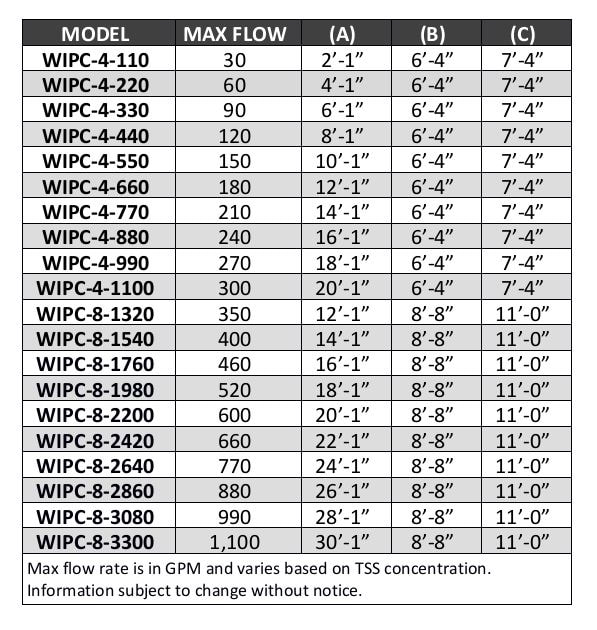

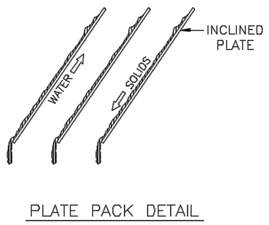

The 55-degree inclined plates are slick UV stabilized polypropylene sheets assembled in bundles with stainless steel rods, PVC spacers and fasteners. The plates are locked in at the proper angle and spacing by a unique design that provides both strength and rigidity. The plate packs are designed to be cleaned in place so maintenance is minimal. Sizes are available from 5 GPM to 1,100 GPM.

OPERATION

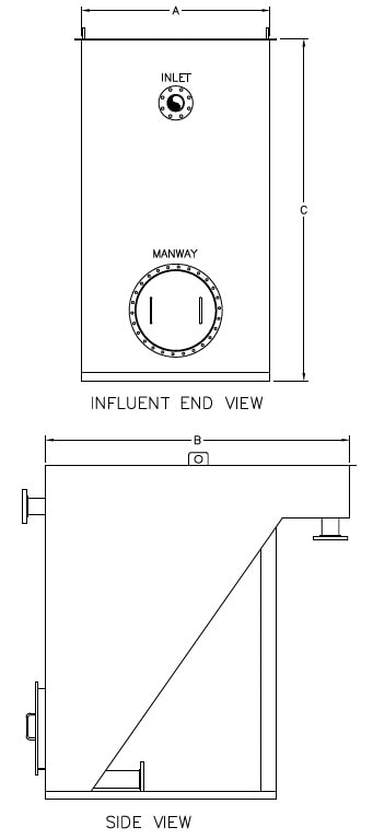

The raw water enters the IPC inlet chamber and is immediately dispersed through a non-clog diffuser across the width of the clarifier, which reduces velocities and turbulent flow, and begins the settling process. The flow leaves the inlet chamber under a weir that directs the flow evenly under the plate pack for heavier solids settling. Fines in the water then begin a vertical path through the plate pack and stop their vertical motion, fall downward to the plate surfaces beneath them and descend into the sludge chamber. Clean water flows upward along the bottom of the plates into the effluent chamber prior to discharge via an effluent flange.

APPLICATIONS

- Air Scrubbers

- Chemical Plants

- Utility Companies

- Manufacturing Process

- Metal Platers

- Mining

- Aircraft Wash Racks

- Groundwater Remediation

- Microprocessors

- Plating Waste

- Stone, Glass, Clay Ind.

- Pulp & Paper

- Automotive

- Fabricated Metal Plants

- Glass Factories

- Metal Hydroxides

- Power Plants

- Steel Mills

HOW DO THE PLATES WORK?

The inclined plates sit at a 55° angle from horizontal and are the heart of the Inclined Plate Clarifier. Descending solids settle on the top of the plates and descend into the sludge chamber, while the clean water flows upward along the bottom of the plates and into the effluent chamber.

Polypropylene plates spaced 1” on center are standard. Fiberglass, PVC and stainless-steel plates are also available, with spacing up to 2”.

MATERIALS OF CONSTRUCTION

The WIPC is offered in A36 carbon, 304 and 316 stainless steel materials. Plate pack is offered in polypropylene, 304 and 316 stainless steel materials. Plate spacing ranges from 1” to 2”, 1” is standard.

AVAILABLE OPTIONS

- Influent Feed System

- Effluent Pump Out

- Sludge Pump Package

- NEMA 7 Controls

- pH Adjustment Systems

- Solids Contact Recycle

- Covers

- Walkways

- Sludge Dewatering