GENERAL INFORMATION

The Westlake Environmental Oil Water Separator (OWS) is the most efficient for removing non-emulsified oils from a wastewater stream that may also contain up to 300 ppm of solids. The coalescing media is configured to allow the oils to rise to the surface and cascade into an isolated oil chamber, while the solids settle into the sludge chamber to be isolated from the flow.

The model OWS will coalesce and concentrate 20 micron and larger free fats, oils and grease from water to produce a clean water effluent of 10 ppm or less free oil. The concentrated oil will have less than 5% water. The separators can be installed above, flush or below grade and can operate by gravity or pumped feed, depending on the application.

OPERATION

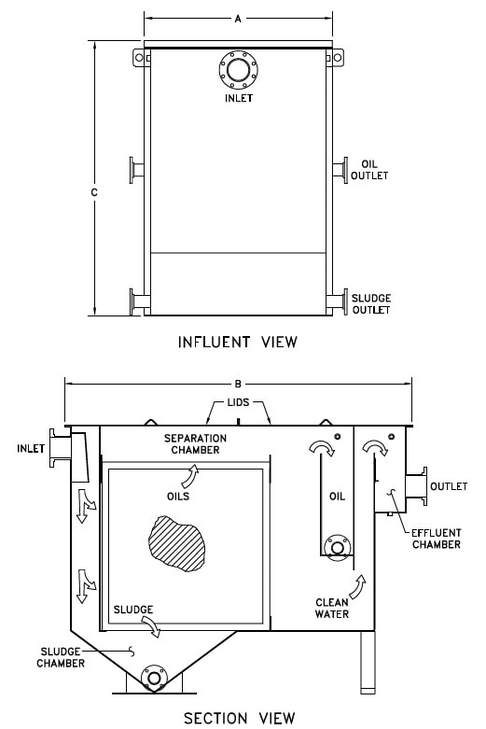

The wastewater enters the OWS influent chamber via a non-clog, energy dissipating baffle that distributes the flow across the width of the coalescing pack. The separation chamber has a Westlake Media Bundle that is filled with oleophilic media that insures collision of the oil droplets, which become larger and quickly float to the water surface. As the oil layer reaches a given height on the water surface, it decants into an integral oil reservoir. The bundle is also designed such that solids will separate and settle into the sludge collection chamber. Clean water flows under a baffle and over an adjustable 304 stainless steel weir into the effluent chamber. Liquid level in the separator is determined by the height of the adjustable weir. The clean water exits the effluent chamber through an outlet flange. Sectionalized, gasketed covers are provided to allow easy access to the separator internals.

MATERIALS OF CONSTRUCTION

Materials of construction include 3/16”-1/4” A36 carbon steel, 304 SS, 316 SS and fiberglass. The standard Westlake Bundle material is Polyvinylchloride (PVC) which is highly oleophilic. The media can also be supplied in CPVC and 304 stainless steel. Plate spacing ranges from 1/2” to 1.2”, 3/4” is standard.

SEE IT IN ACTION

APPLICATIONS

- Airports

- Bus Terminals

- Glass Factories

- Oil Fields

- Pulp & Paper Mills

- Railroad Yards

- Automotive

- Chemical Plants

- Groundwater

- Petroleum Plants

- Parking Lots

- Truck Terminal

- Bulk Plants

- Fabricated Metal Plants

- Processing Plants

- Military Bases

- Refineries

- Utility Companie

WESTLAKE BUNDLE

The Westlake Bundle is oleophilic material used to increase the size of oil droplets. When placed in the flow path of oily water, the oil droplets collide with each other and impinge on the surface of the media. The fine separated oil droplets combine, coalesce, and become a large easily removed oil drop that rapidly rises to the surface of the separation chamber. The most common media is PVC. In the event a wastewater stream is too hot to use PVC, a 304 stainless steel material is utilized.

AVAILABLE OPTIONS

- Complete Pump Packages

- Sludge Auger

- Level Switches

- NEMA 7 Controls

- Optional Media Materials

- Freeze Protection

- Expanded Oil & Effluent Capacity

- Custom Tank Design & Control Logic To Satisfy Your Application